As the world grapples with the escalating crisis of climate change, innovative approaches to carbon dioxide (CO2) capture are more essential than ever. A recent groundbreaking study published in the journal Advanced Materials unveils a remarkable advancement in this arena: the development of porous polymeric electrodes (PPEs) that significantly increase the efficiency of CO2 capture, particularly from sources with low concentrations of the gas. Led by Professor T. Alan Hatton, the research team has crafted a material that presents a game-changing opportunity in the fight against greenhouse gas emissions.

The unique composition of PPEs lies in their innovative construction using a combination of widely available materials: melamine foam coated with polyvinyl alcohol, combined with carbon nanotubes and quinone molecules. This synergy allows for unparalleled interaction between CO2 and the capturing material, enhancing gas transport characteristics. The porous design of these electrodes not only serves to amplify the active surface area but also plays a vital role in creating a streamlined, effective process for CO2 capture.

The performance metrics of these electrodes are noteworthy. Achieving an impressive utilization rate of up to 90% for the active capture material, the new PPEs demonstrate a CO2 capture capacity that varies between 30 to 80 kg per cubic meter per day, dependent on CO2 concentration levels. This efficiency outstrips that of existing carbon-based electrodes, marking a pivotal stride forward in the realm of electrochemical carbon capture.

One of the standout features of the porous polymeric electrodes is their remarkable resilience. The material shows excellent performance through over 100 capture-release cycles while maintaining stability under humid conditions. This reliability addresses a major concern for real-world applications, where environmental fluctuations often undermine the efficacy of carbon capture technologies. Moreover, the design cleverly eliminates the need for separate gas diffusion layers, leading to more compact systems that could potentially lower production and operational costs.

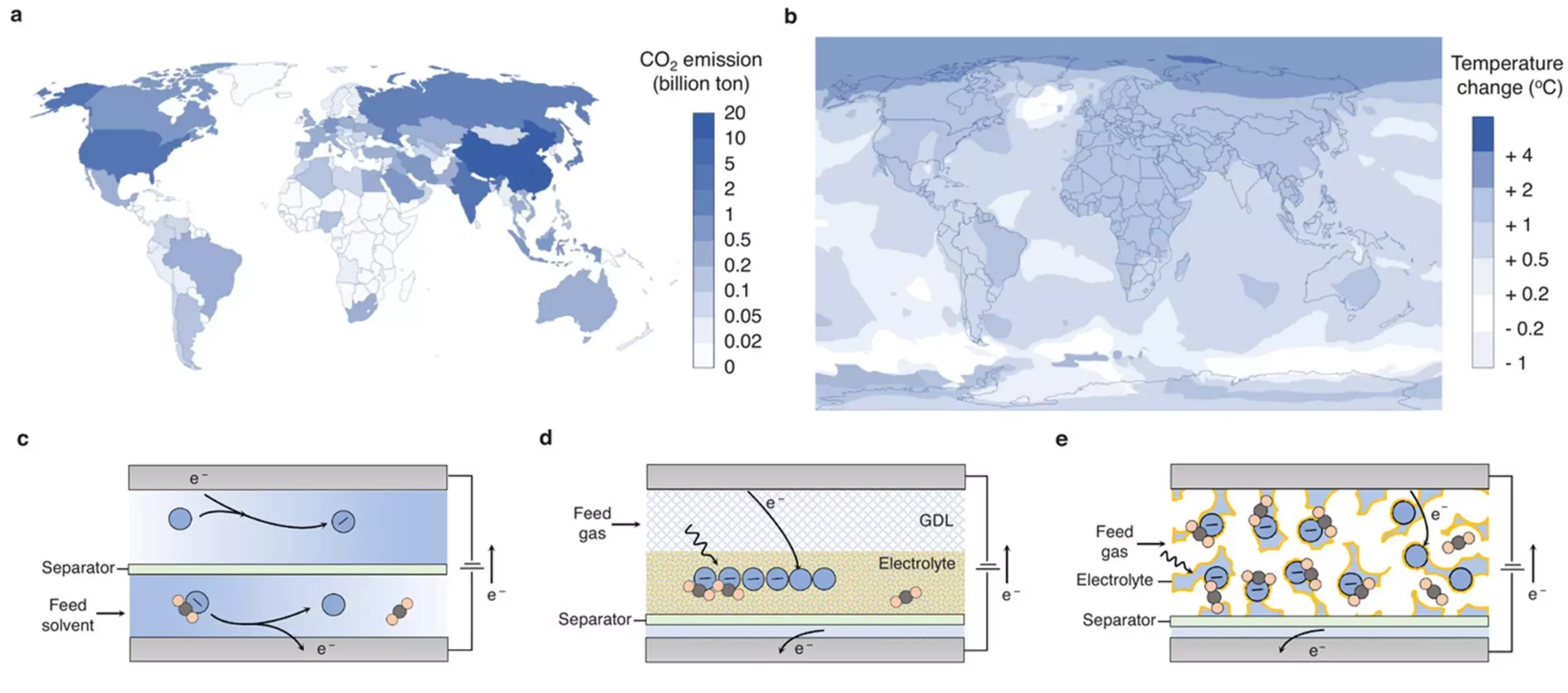

The versatility of these electrodes further expands their potential applications, ranging from direct air capture to lowering emissions from industrial processes. By demonstrating the capacity to effectively capture CO2 from both air and dilute gas streams, the technology paves the way for a variety of innovative implementation strategies.

In light of recent reports from the Intergovernmental Panel on Climate Change (IPCC), the urgency for effective carbon capture solutions has never been more pressing. Innovations like the porous polymeric electrodes can significantly bolster efforts to meet ambitious net-zero targets, making a substantial difference in reducing atmospheric CO2 levels. Although the results from this research are promising, the team acknowledges that further optimization and scaling up of production are necessary for widespread application.

As we look toward the future, the development of PPEs could prove crucial in the global endeavor to mitigate climate change. This breakthrough, harnessing common materials to create an exceptionally efficient carbon capture solution, not only exemplifies the ingenuity of contemporary research but also highlights the importance of ongoing innovation in the chase for sustainability. The road ahead demands diligent work to refine these technologies, but with perseverance and creativity, steps toward a more sustainable world are not only possible but within reach.