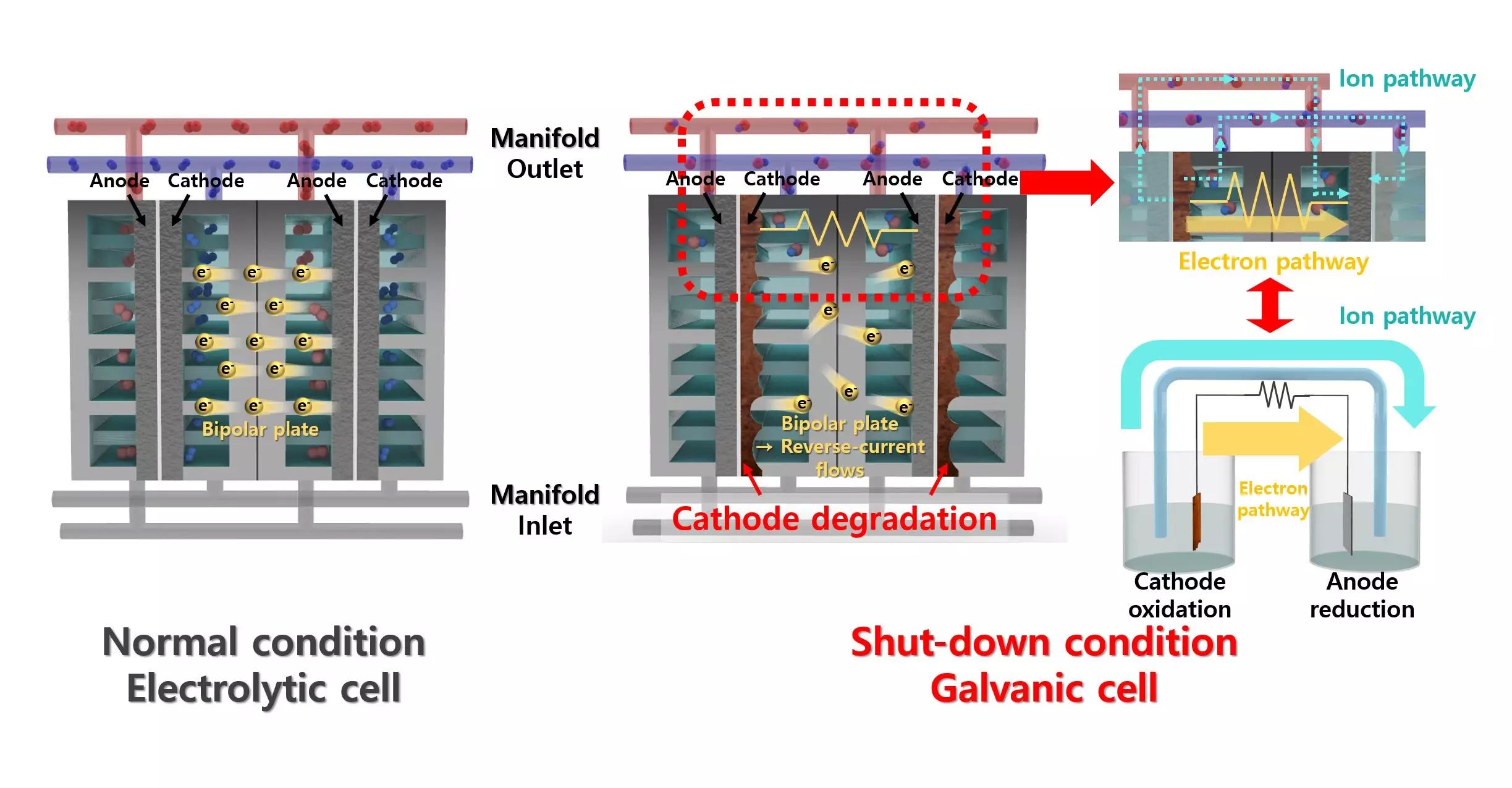

In our quest for sustainable energy, one of the significant challenges we face is the inconsistency and sporadic nature of renewable sources such as solar and wind. As these energy inputs are not always reliable, developing effective methods for energy storage and delivery becomes paramount. Hydrogen has emerged as a key player in this equation due to its versatility and potential for clean fuel applications. The hurdles, however, are well-documented, particularly in water electrolysis systems, where maintaining efficiency under fluctuating energy conditions is a complex challenge.

A Quantum Leap in Catalyst Technology

The recent research spearheaded by an innovative team, consisting of distinguished scholars from Pohang University of Science and Technology (POSTECH) and Seoul National University, heralds a new era in hydrogen production via alkaline water electrolysis (AWE). Led by Professor Jeong Woo Han and aided by the expertise of Professor Yong-Tae Kim and their colleagues, this collaborative research highlighted a breakthrough catalyst that minimizes degradation typically associated with reverse current scenarios. Their findings, featured as a cover article in Advanced Functional Materials, encapsulate a significant advancement toward more efficient hydrogen evolution reactions.

Enhancing Durability Through Novel Approaches

The breakthrough lies in the application of an uncommon yet strikingly transformative approach: the integration of a lead (Pb) coating over a nickel (Ni) catalyst. Traditionally, lead has been sidelined in catalysis due to its lack of activity in hydrogen evolution reactions; however, this research illustrates how its properties can enhance performance when strategically applied. By acting as a co-catalyst, lead facilitates key processes such as proton desorption and water dissociation – crucial steps in achieving high efficiency for hydrogen production.

In a rather stark contrast to common methods that necessitate sophisticated additional equipment or complex processes to counteract reverse current issues in AWE systems, this novel catalyst sufficiently addresses the problem using just the lead coating. The researchers established that their catalyst stands resilient against reverse current, maintaining effectiveness even during repeated operational cycles of starting and stopping the AWE process.

A Breakthrough Implication for Future Research

The implications of this research extend far beyond simple operational efficiency. By addressing a fundamental vulnerability in alkaline electrolysis systems, this study sets a precedent for future innovations in catalyst design. The prospect of a more cost-effective and mechanically sound hydrogen production system holds promise for the broader energy sector, particularly regarding the integration of renewable sources into conventional grids.

The primary author, Professor Yong-Tae Kim, emphasized the significance of this research by declaring it as the first to effectively address the issue of degradation due to reverse currents in AWEs. This sentiment underscores a vital belief in the potential to revolutionize not just hydrogen production, but to redefine strategies in energy sustainability as we transition into a more reliant, greener future. The potential of this work fuels optimism for both academic and industrial advancements in clean energy technologies and paves the way for sustainable innovation on a global scale.