The transition to a sustainable energy future has prompted a global push toward clean energy solutions. Among these, green hydrogen stands out as a particularly compelling alternative. This clean fuel is generated through electrochemical processes that involve splitting water into hydrogen and oxygen using renewable energy sources like solar and wind. The U.S. Department of Energy has set ambitious goals for the adoption of green hydrogen, seeing it as a cornerstone of their plan to achieve net-zero carbon dioxide emissions. However, producing green hydrogen at an industrial scale has come with significant challenges, particularly in optimizing the efficiency of the electrochemical reactions necessary for hydrogen generation.

Conventional Methods: The Bottleneck

Traditionally, the production of hydrogen via proton exchange membrane electrolyzers (PEMEs) has encountered inefficiencies that hinder its advancement. In these systems, water molecules are decomposed into hydrogen and oxygen gases at the electrodes, but the process is often imbalanced. While hydrogen can be produced relatively quickly, the production of oxygen is considerably slower. This discrepancy poses a bottleneck that limits the overall efficacy of current processes. Essentially, the sluggish oxygen generation limits the flow of electrical current, thereby reducing the yield of green hydrogen.

A Breakthrough in Catalysis: Defect Engineering

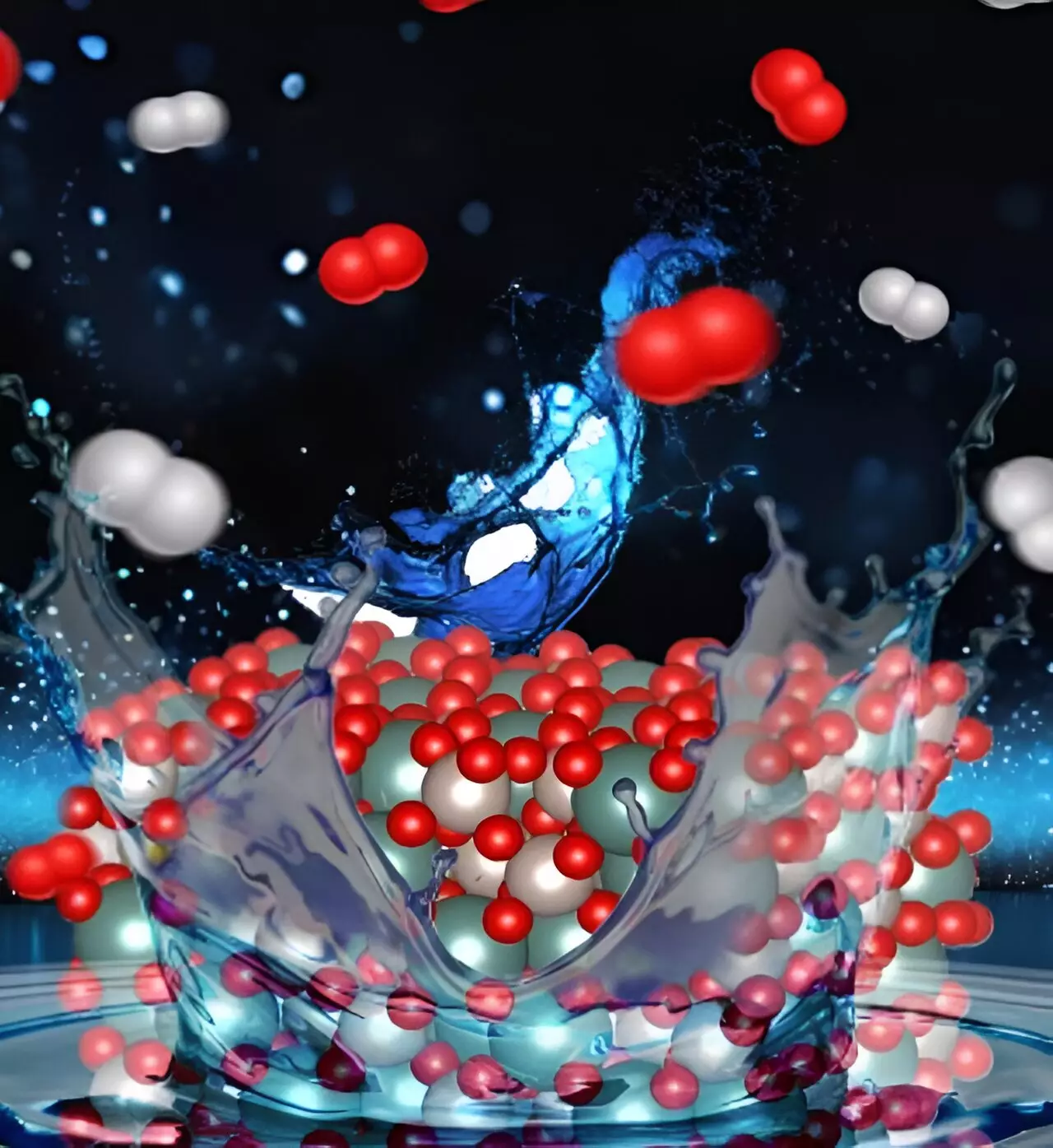

Fortunately, recent research has reignited hope in the quest for efficient green hydrogen production. An interdisciplinary research team has made groundbreaking progress by employing a strategy known as “defect engineering.” This innovative approach focuses on modifying the electronic properties of catalyst materials, improving their efficiency. The study, led by Hong Yang, a professor of chemical and biomolecular engineering, incorporates the use of ruthenium as a foundational material for a new complex oxide electrocatalyst designed to expedite oxygen generation.

Unlike traditional designs, which aim for perfection, defect engineering embraces the deliberate introduction of imperfections or “defects” into the catalyst. These imperfections can modify the catalyst’s electronic structure, enhancing its performance. This method draws parallels with semiconductor technology where the introduction of impurities into silicon chips is essential for their functionality.

Yttrium’s Role in Catalytic Performance

In the innovative study, the researchers incorporated yttrium atoms alongside ruthenium in the electrocatalyst’s composition. The substitution of ruthenium with yttrium resulted in a notable enhancement in oxygen generation rates. This surprising outcome challenges conventional wisdom, which often assumes that increasing the concentration of reactive elements would directly influence performance.

Initial hypotheses suggested that an increase in the concentration of oxygen might correlate with enhanced catalytic activity. However, the findings revealed an essential distinction: the amount of oxygen within the materials remained unchanged. Instead, the oxidation state and electronic configuration of ruthenium were primarily responsible for the observed improvements. This insight signifies a pivotal moment in our understanding of electrocatalyst design and holds promise for future innovations.

Analysis of Interactions: The Science Behind the Catalyst

The research utilized advanced techniques, such as thermogravimetric analysis, to measure the impact of varying compositions on the electrocatalyst’s reactivity. This level of scrutiny allowed the team to quantify the oxygen vacancy created in the material. The results led to a paradigm shift in understanding the interactions at play in effective catalysis. Researchers highlighted that the enhancements were achieved without an increase in missing oxygen atoms, illustrating the crucial role played by the modified electronic structure.

Yang eloquently states the necessary balance: “One cannot just randomly create a less-perfect material and expect improved performance.” This delineates the sophistication behind defect engineering, which requires meticulous control over the types and levels of imperfections to optimize catalysis effectively.

Importance of Interdisciplinary Collaboration

The study’s triumph underscores the value of interdisciplinary collaboration in scientific advancements. The challenge of characterizing new electrocatalysts is not one any single field can tackle in isolation. A diverse team combining expertise from chemical engineering and material science proved essential in overcoming obstacles and achieving meaningful results. Combining their collective knowledge facilitated a holistic understanding of the systems examined and carried implications that extend beyond green hydrogen production alone.

As research into advanced catalysis progresses, the integration of knowledge from various scientific fields will ultimately catalyze the propulsion of green hydrogen into mainstream energy viability. The potential applications are vast—ranging from sustainable energy storage to broader implications for tackling climate change. The advancements in this arena could not only change the trajectory of hydrogen production but also pave the way for a cleaner, more sustainable planet.