Gas separation plays a crucial role in numerous industries, from healthcare to energy production. The necessity to isolate gases like nitrogen and oxygen for medical use or capturing carbon dioxide during combustion processes is paramount. However, the existing methods for separating these gases are notably energy-consuming and costly. Traditional separation techniques mandate extreme cooling to liquefy air, followed by a gradual warming process that facilitates the evaporation of gases at distinct temperatures. Professor Wei Zhang from the University of Colorado Boulder poignantly describes this as an “energy-intensive and costly” endeavor, highlighting the inefficiencies that plague current gas separation practices.

The financial and environmental costs associated with prevailing techniques broaden the conversation around sustainable innovations in gas separation. While various sectors strive to cut down energy expenditure and reduce greenhouse gas emissions, the limitations of existing methods lend themselves to an urgent call for technological advancements.

Innovative Porous Materials: A Game-Changer

Recent research published in the journal *Science* introduces a groundbreaking development in gas separation technology through innovative porous materials designed to overcome inherent shortcomings. Traditional porous materials have been rigid, optimized for specific gas separations and unable to pivot to the requirements of different gas mixtures. This has hindered their utility in environments where gas composition is not predetermined.

Zhang’s research group has pioneered a unique porous structure that employs both rigidity and flexibility, allowing for multiple gases to be separated with reduced energy costs. The novel aspect lies in the introduction of oscillation in the linker components, adjusting pore size dynamically based on temperature. At lower temperatures, the porous material readily accommodates most gases, whereas at elevated temperatures, the oscillation increases, reducing pore size and selectively filtering out larger gas molecules. This versatility injects a level of efficiency and adaptability that has long been missing from the field.

By shifting away from the conventional method of rigid, gas-specific porous materials, Zhang’s team sets the stage for broader applications yet to be fully explored. The exciting part is that they utilized common, accessible materials, making this technology scalable and sustainable without relying on rare resources.

The Science Behind the Breakthrough

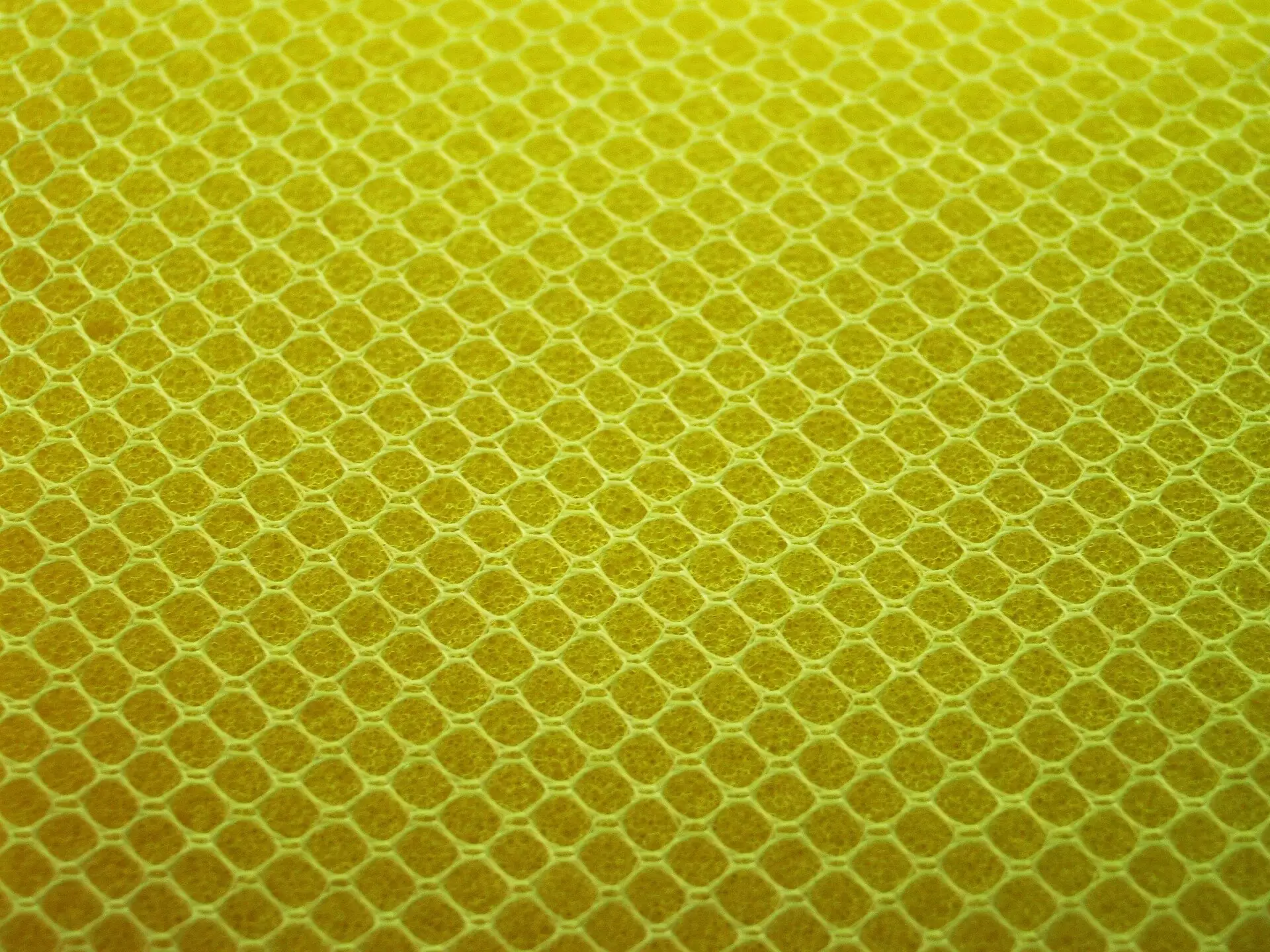

The material synthesizes a family of small organic molecules to create a honeycomb-like structure reminiscent of zeolites. This type of porous material consists of ordered channels lined with uniformly sized pores, which is crucial for effective and efficient gas separation. The clever incorporation of boron-oxygen bonds into the molecular framework enables a dynamic configuration. The reversibility of these bonds fosters a self-correcting mechanism, ensuring that the material can adapt and respond to varying gas types.

Zhang explains how initially, the research team faced a labyrinth of challenges attempting to elucidate the structural characteristics of their new material. The peaks observed in X-ray diffraction experiments suggested promising results, but they could not initially interpret what these patterns represented. Instead of pushing through with assumptions, they appropriately pivoted to a smaller model system that could yield insights relevant to their observations. This reflects an often-overlooked aspect of scientific inquiry: the value of adaptability and patience in research processes.

Looking Ahead: Scalability and Industry Integration

The team envisions tremendous potential for this invention, particularly in industrial scenarios requiring substantial quantities of gas separation. The researchers have already taken steps towards commercial viability by applying for a patent and exploring partnerships within engineering disciplines to facilitate membrane applications. With membrane separation recognized as a method requiring significantly less energy than traditional techniques, this innovation aligns perfectly with modern sustainability goals.

Zhang remains optimistic about the pathway ahead, indicating that the building blocks for this technology are economically viable and readily available. This accessibility could usher in a new era for industries reliant on gas separation, transforming operations while simultaneously contributing to climate change mitigation efforts.

As tech-oriented solutions to age-old problems continue to emerge, it becomes abundantly clear that innovations like those spearheaded by Zhang’s team are not just scientific curiosities—they are pivotal steps toward a greener, more efficient industrial future. This new wave of research represents a thoughtful blend of flexibility, responsiveness, and scalability that promises to redefine the standards in gas separation technology.