Traditionally, voids or pores within materials have been dismissed as detrimental imperfections, undermining their structural integrity and mechanical properties. Manufacturers have tirelessly sought to eliminate these flaws in pursuit of materials with superior performance characteristics. However, a groundbreaking study led by Professor Jin Haijun from the Institute of Metal Research of the Chinese Academy of Sciences has revealed a surprising angle: when strategically incorporated, voids can actually enhance material performance. This revelation has the potential to redefine how engineers and materials scientists approach the design and fabrication of metallic structures.

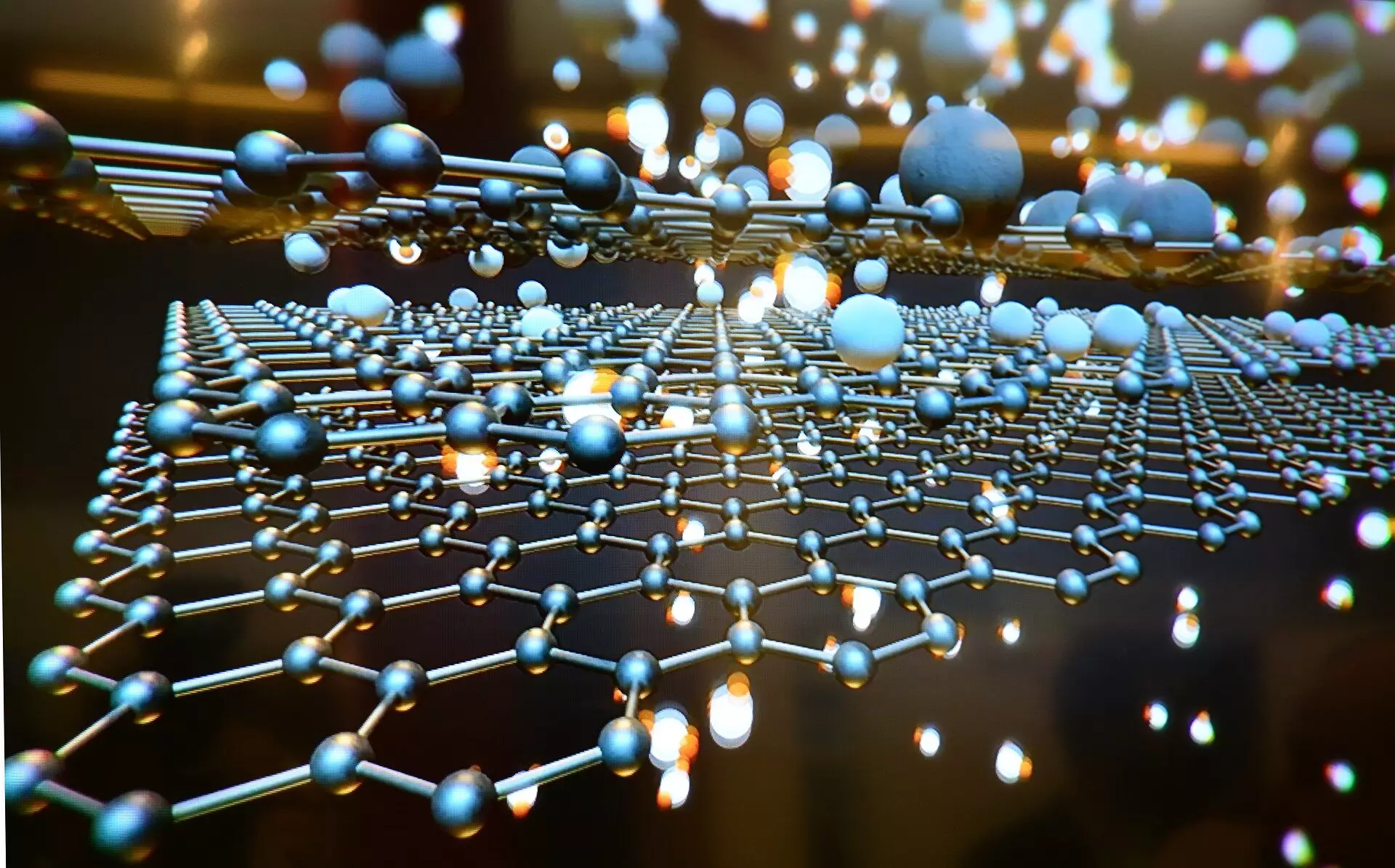

The research team unearthed a unique form of gold, termed nanovoid dispersed gold (NVD Au), which exhibits numerous nanoscale voids dispersed throughout its structure. Ranging from a few nanometers to several hundred nanometers in size, these voids are not merely incidental; they are positioned with intention, leading to remarkable improvements in mechanical performance compared to conventional solid gold samples. Published in the prestigious journal Science, this study challenges previously held beliefs and opens the door for innovative applications in a variety of industries.

The creation of NVD Au involves a complex interplay of processes including dealloying, which is a form of corrosion, followed by compression and thermal annealing. This multifaceted approach allows researchers to cultivate the beneficial voids while ensuring the material retains its desirable physical and chemical properties. The outcome is a lightweight yet strong material, capable of bearing substantial loads without fracturing—a quality that is especially advantageous in applications ranging from portable electronics to aerospace engineering.

Results indicate that the presence of nanovoids contributes positively to the material’s tensile strength and ductility. The NVD Au exhibited an exceptional ability to endure greater stresses and elongate significantly prior to rupture. This is a stark contrast to the detrimental effects observed in materials with larger voids, often resulting from methods such as powder sintering or additive manufacturing. The enhanced performance of NVD Au is primarily attributed to improved interactions within its internal structure, particularly between dislocations and the surfaces surrounding the voids, alongside a remarkable suppression of crack formation.

The implications of this research extend far beyond the realm of gold alone. The methodology for creating NVD materials could inspire novel designs across a spectrum of materials, revolutionizing sectors that rely heavily on metals and alloys. Whether in telecommunications, aviation, or automotive manufacturing, the possibility of lightweight materials with superior mechanical properties presents an exciting frontier. As Professor Jin Haijun notes, this study signifies a significant advancement in material science, suggesting that a paradigm shift may be imminent—one where voids are harnessed as a strength rather than viewed as a flaw. This paradigm could enhance efficiencies, reduce material costs, and promote sustainability in manufacturing practices.

The research on nanovoid dispersed gold not only promotes the advantages of strategic void incorporation but also encourages a broader reconsideration of material design principles. As scientists continue to explore the balance between structural integrity and innovative design, it is evident that the future of material science is brighter than ever.