Piezoelectric materials are integral to the functionality of advanced technologies such as ultrasound and sonar systems. These materials can convert mechanical stress into electrical energy and vice versa, allowing them to play crucial roles in applications ranging from medical imaging to underwater exploration. The effectiveness of piezoelectric materials is primarily dictated by their ability to maintain a certain alignment of internal dipoles, which significantly influences their piezoelectric properties. Yet, a persistent challenge has been ensuring this alignment remains intact under various external conditions, particularly elevated temperatures and high pressures.

The recent study published in *Nature Communications* introduces a groundbreaking technique to restore the piezoelectric properties of these materials at room temperature, fundamentally transforming the maintenance and repair landscape for ultrasound devices. Historically, to rectify misalignment caused by heat or pressure, technicians would have to disassemble complex devices and expose the materials to extreme temperatures upwards of 300°C. This not only poses logistical challenges but also risks diminishing the lifespan and functionality of the devices involved.

To understand the newfound technique, it’s important to grasp the polarization process underlying piezoelectric materials. These materials, particularly those classified as ferroelectric like relaxor-PbTiO3, exhibit spontaneous polarization due to the presence of dipoles—pairs of positively and negatively charged ions. The alignment of these dipoles is vital; when they are properly aligned—through a process known as poling—the material’s ability to generate and respond to ultrasound waves is enhanced significantly.

As explained by Xiaoning Jiang from North Carolina State University, the preservation of this alignment is fraught with difficulty. External factors—ranging from the moderate temperatures experienced during storage to the operational heat generated by the devices themselves—can lead to a degradation of piezoelectric properties. Conventional methods to rectify misalignment require extensive intervention, often resulting in the costly disposal of functioning components.

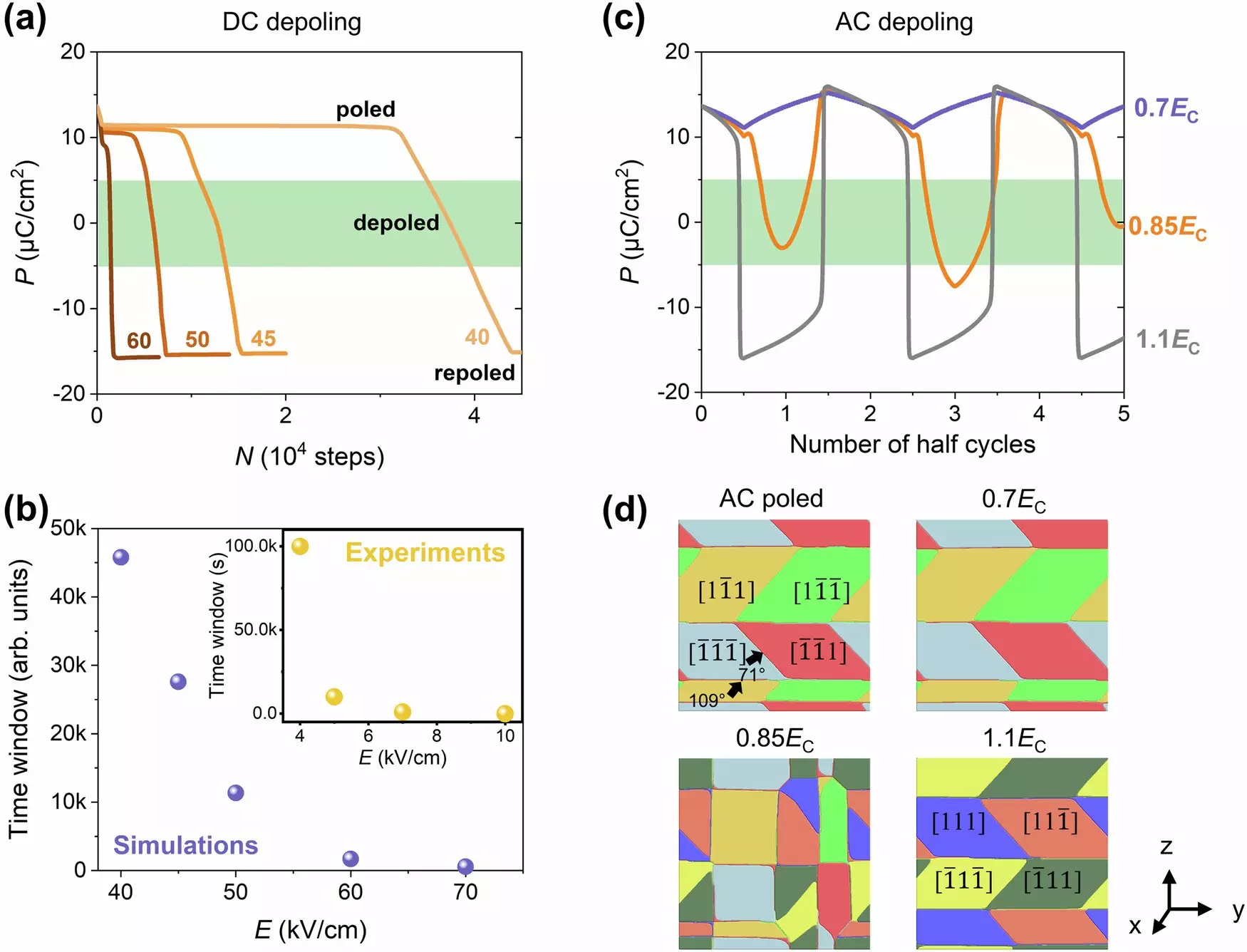

The innovative research has unveiled a procedure that allows the alignment of dipoles at room temperature, which can be executed without disassembling the devices. This revelation is pivotal for manufacturers and end-users alike, making repairs significantly more feasible and cost-efficient. The essence of the technique lies in the application of an alternating current (AC) electric field to the material, which can effectively depole it—removing the existing dipole alignment—without the need for high heat.

Historical methods of using a direct current (DC) field to align dipoles are cumbersome, particularly because they lack efficiency when it comes to depolarizing materials. In contrast, the application of an AC field permits oscillation of dipoles, allowing for complete depoling under the right conditions. Jiang and his team have demonstrated that if a material was initially poled using an AC field, it could subsequently be fully depolarized using the same AC technique at room temperature.

The implications of this breakthrough are two-fold. Firstly, it signifies a dramatic departure from traditional constraints on the types of materials and manufacturing processes that have previously been deemed compatible with piezoelectric applications. With room-temperature poling techniques available, manufacturers can now consider a broader range of materials that may enhance the performance of ultrasound devices.

Secondly, the ability to restore piezoelectric properties on-site without extensive disassembly affords substantial operational advantages. This could lead to a decrease in waste as components could be continually reused without the need for expensive replacements. Jiang points out that maintaining the integrity of these costly materials can have significant economic benefits rather than having to discard entire devices simply because a small component failed.

The development of room-temperature techniques for the depoling and repoling of piezoelectric materials marks a significant milestone in materials science. By drastically simplifying the repair process, this advancement not only improves the longevity and functionality of ultrasound and sonar devices but also opens the door for innovations that could enhance performance across various applications. As researchers continue to explore the ramifications of this technique, the future of ultrasound technology looks brighter than ever.