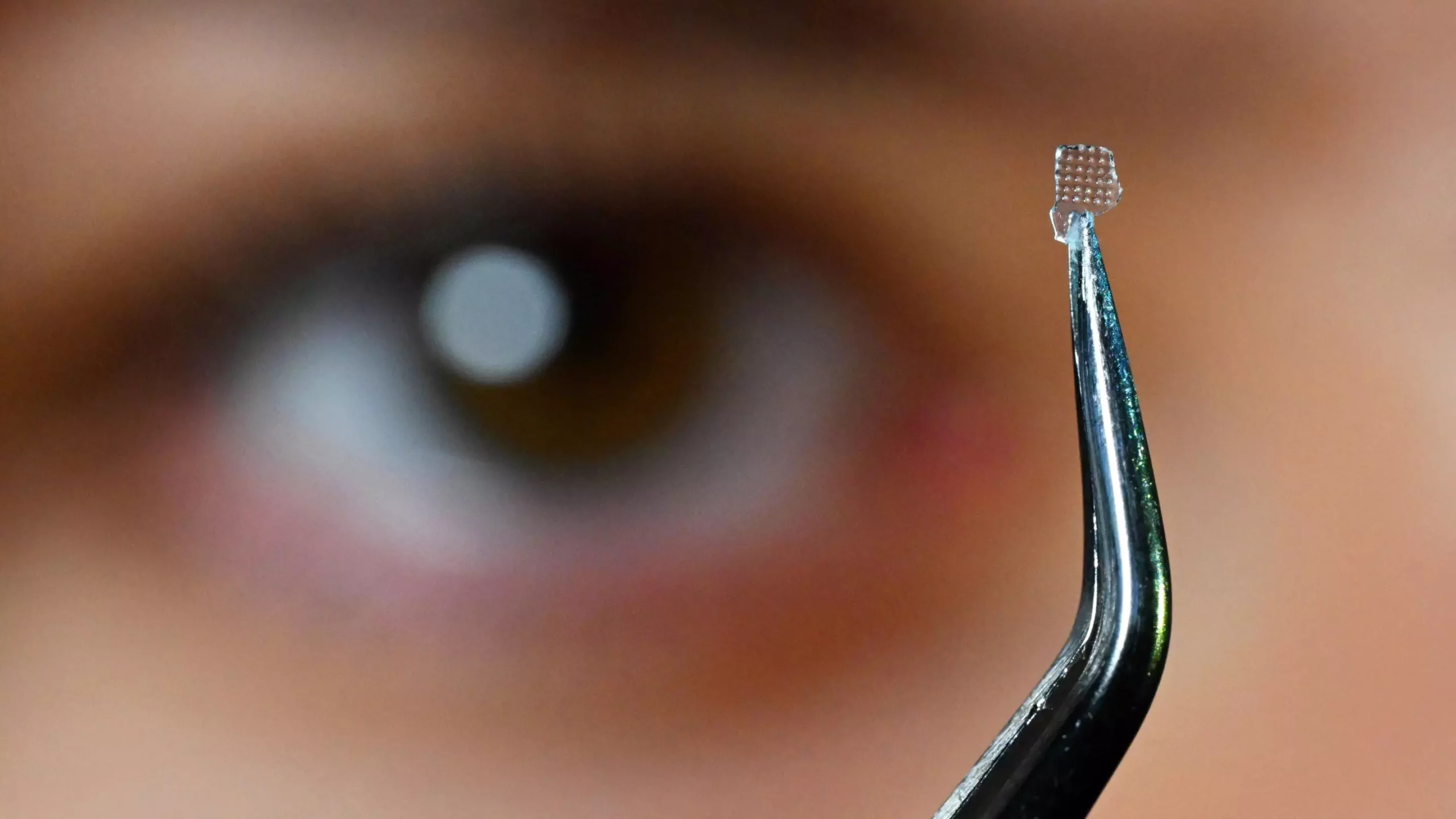

The recent innovation from a team at the University of Jena has ushered in a new era of intelligent optical lenses, designed with remarkable precision on a microscopic scale. This pioneering development involves micro-lenses that exhibit responsive refractive behavior when exposed to gas. The potential applications for these lenses promise to vastly improve optical technologies across various fields, including telecommunications, environmental monitoring, and sensor technologies. Leveraging a novel hybrid glass material, these lenses open avenues that push the traditional boundaries of lens technology.

Hybrid Glass: Revolutionizing Optical Properties

At the heart of this groundbreaking innovation lies advanced hybrid glass, characterized by a unique three-dimensional lattice structure. This structure contains intricate cavities capable of trapping gas molecules, fundamentally altering how light passes through the material. Professor Lothar Wondraczek remarks on this material’s versatility, noting that its refractive qualities can be manipulated actively in response to gas absorption. This property directly impacts optical clarity and may provide unprecedented control in various practical applications.

The adaptability of such materials represents an extraordinary leap forward, encapsulating what scientists have long sought: an optical element responsive to its environment. The implications of this ability are virtually limitless, promising enhanced functionalities in everything from portable electronics to complex scientific instruments.

Innovative Synthesis and Shaping Techniques

Developing these micro-lenses presented substantial challenges, particularly in the synthesis of a highly pure hybrid glass material. Doctoral candidate Oksana Smirnova and her colleagues worked diligently to overcome the historical limitations associated with metal-organic frameworks, which often degrade under heat. Their efforts culminated in establishing a new synthesis process, allowing for precise molding of the material into complex geometries.

The ability to employ 3D printing for mold creation marks a significant advancement. By controlling the shape and ensuring optimal conditions during the melting process, researchers can fabricate lenses that meet exacting standards. The deliberate choice to focus on lens shapes further underscores the critical nature of purity in optical applications, as even minor impurities can lead to significant optical distortions.

Multiplicative Benefits: Applications Beyond Lenses

The multifunctionality of these materials contributes to their potential utility beyond traditional optics. Wondraczek hints at innovative applications in logical circuits, where the micro-lens can serve as a pivotal element for simultaneous condition detection. If light interacts with the lens concurrently with gas absorption, one may achieve specific refractive patterns generated by dual stimuli, signifying a new dimension in responsive material technology.

Moreover, the concept of developing membranes that alter optical characteristics based on gas presence could revolutionize sensing technologies and environmental applications. By integrating optical properties with gas separation, researchers can create tools that not only detect but also respond proactively to environmental changes.

The integration of such intelligent materials into existing systems demonstrates a critical shift in engineering paradigms, marrying optics and chemistry towards unprecedented advancements. As these innovations unfold, the intersection of gas interactions and optical manipulation identifies a promising frontier, with implications that could redefine entire industries.