In a world increasingly governed by technology, the ability to manipulate materials at the molecular level presents an unparalleled opportunity for innovation. The realm of molecular devices has seen remarkable progress, particularly in how solid-state structures can be engineered to perform sophisticated mechanical functions. Researchers from the Ulsan National Institute of Science and Technology (UNIST) in South Korea, under the leadership of Professor Wonyoung Choe, are at the forefront of this revolutionary exploration. Their pioneering work delves into zeolitic imidazolate frameworks (ZIFs) that not only replicate complex machinery but do so with impressive precision, thus heralding a new chapter in the fields of nanotechnology and data storage.

Mimicking Nature’s Solutions

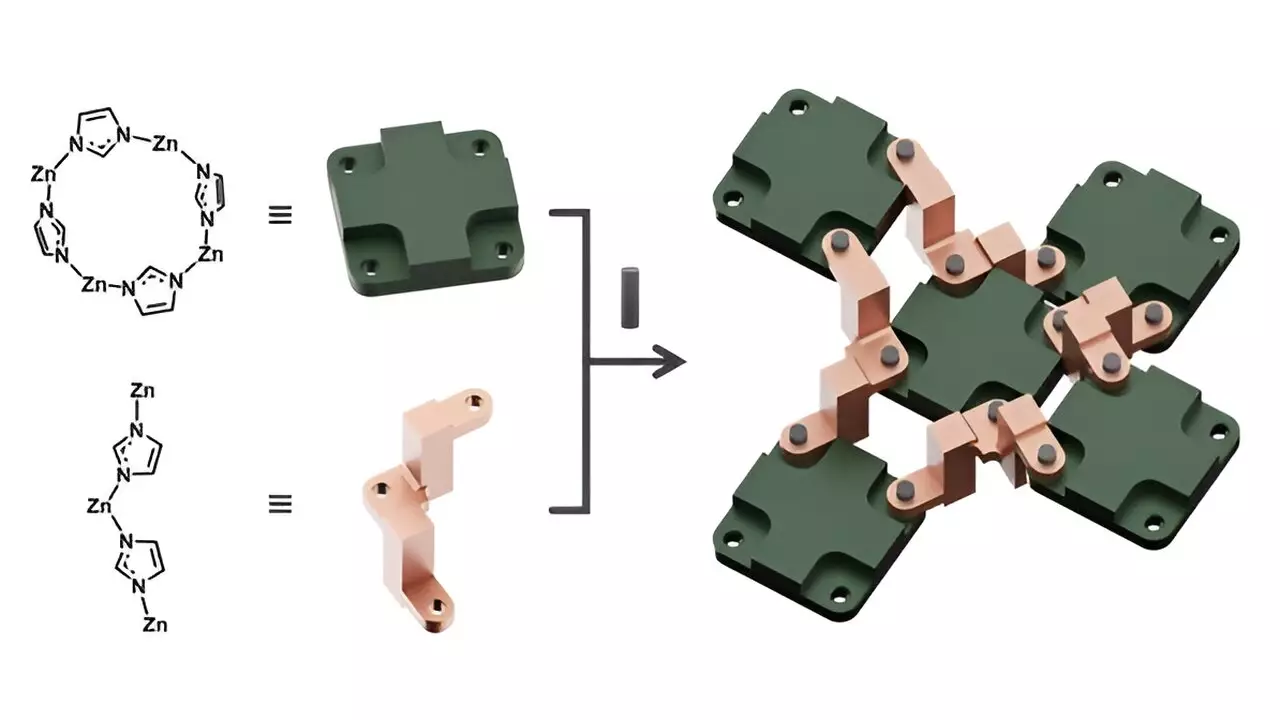

What makes this research particularly exciting is its inspired design, echoing the intricate mechanical systems found in nature. The team has cleverly used metal-organic frameworks (MOFs) to build these nanoscale machines. By embedding molecular mechanisms—akin to gears and levers—within these frameworks, they have created devices that can execute controlled movements. Historically, the potential to connect mechanical properties with the functionality of MOFs had been elusive, with few instances of successful implementation. However, this new approach employs single-crystal X-ray diffraction to demonstrate how these ZIFs mirror mechanical linkages, akin to the complex interactions in larger, macroscopic machines.

Responsive Engineering at the Nanoscale

One standout feature of these newly engineered ZIFs is their use of slider-crank linkages, a principle that translates the rotational forces into linear motion. The implications of this design are profound, offering a mechanism that can react to environmental changes, such as temperature and solvent interactions. This responsive capability is crucial for applications requiring adaptability. As researchers swap various mechanical components within the ZIF structure, precision in nanoscale movements is not just an ambition—it is becoming a reality.

Elasticity: A Fundamental Asset

Moreover, the research has highlighted the extraordinary elasticity and flexibility of these molecular machines compared to their predecessors. This unique mechanical advantage positions the ZIF as an ideal candidate for applications beyond mere data storage; it opens avenues for advancements in smart materials that can respond dynamically to external stimuli. The flexibility to connect metal nodes and organic ligands in varied manners emphasizes the need for machines designed with adaptability in mind, a critical factor in the future of nanotechnology.

Charting the Path Forward

The scientists at UNIST are not just tinkering with materials; they are crafting the future of nanotechnology with every breakthrough. The discovery of how different connectivity between components affects the flexibility of the ZIFs creates a roadmap for future research in innovative nanomaterials. Professor Choe’s assertion regarding the potential of molecular-level movements to yield materials with unprecedented mechanical properties resonates strongly as we stand on the precipice of a new technological renaissance. The intersection of chemistry and engineering in this domain is set to redefine what we understand about material capabilities in the years to come.